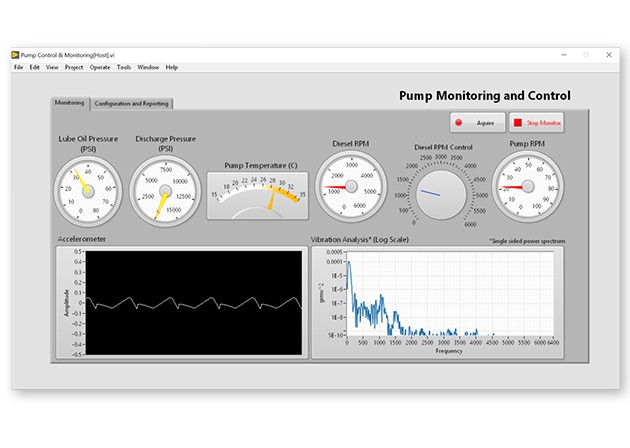

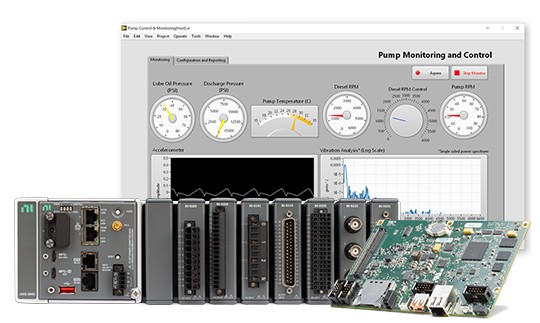

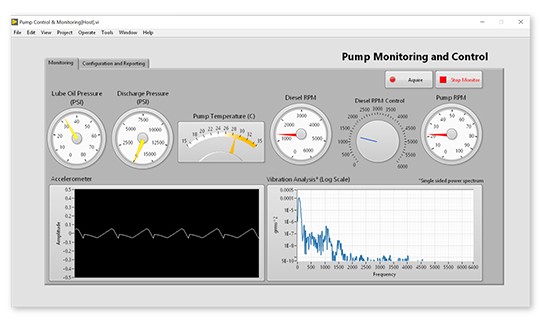

Create and deploy real-time, distributed system applications for test, monitoring, and control with the LabVIEW Real-Time Module:

LabVIEW provides an intuitive graphical programming approach so you can develop real-time applications faster.

LabVIEW Real-Time has hundreds of available LabVIEW libraries and hardware APIs to save valuable development.

LabVIEW Real-Time OS ensures reliability and precise timing in your stand-alone system.